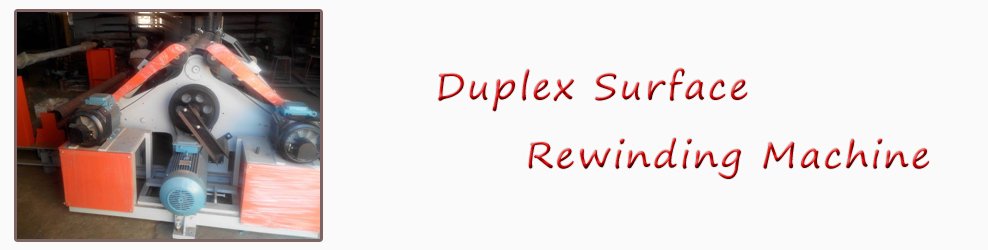

ACCU - Duplex Center Surface Rewinding Machine

To understand the above techniques, it is necessary to understand the terms "Duplex" Surface Rewinding".

The term Duplex Rewinding implies the use of two shafts for Rewinding the slit substrate. This ensures a positive separation between adjacent slit reels, which are wound alternately on the two shafts.

In Surface Rewinding, the web is driven by the winding drum which is always in contact with the outer layer of the material being rewound. Here, it is the winding drum which is driven, also by a motor in most cases.

As is clear by the above definitions, in the case of Center-Surface Rewinding, the winding force is derived from both the Rewind shaft and the contact with the winding drum. Here, both the Rewind shaft and the winding drum are driven by through a clutch mechanism and motor respectively.

The machines using Center-Surface Rewinding technology are simple in construction with a minimal role of electronics and have offered invaluable service to the Flexible Packaging and Converting industry in its nascent stages.

Center-Surface Rewinding technology was commonly used because of its ability to produce large diameter slit reels tight enough to handle the rigors of transportation to the customer. Since the winding drum is not required to transmit increasing torque with the build up in reel diameter, tightness was achieved without the need for complicated drives and controls.